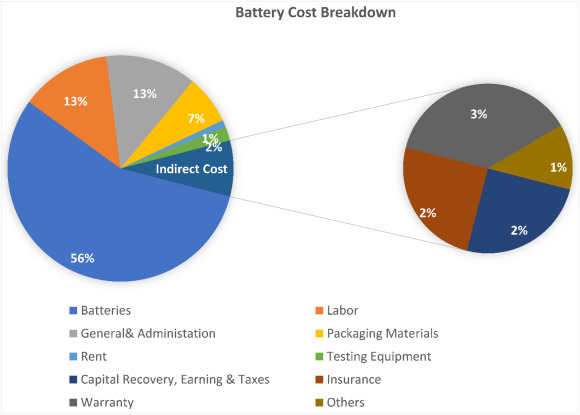

In today’s rapidly evolving tech landscape, batteries serve as the lifeblood of our devices, powering everything from our smartphones to electric vehicles. As technology continues to advance, understanding the intricacies of battery pricing becomes essential. In this exploration, we delve deep into the world of batteries, breaking down their prices into three critical components: the materials used, the manufacturing process, and the mysterious markup that can significantly affect the final cost. But fret not; along the way, we’ll also guide you to get affordable prices here for your device’s accessories.

Setting the Stage for Battery Price Analysis

Batteries have become ubiquitous in our lives, and yet, their pricing can seem like a well-guarded secret. This article aims to shed light on the factors that determine the cost of batteries, helping consumers make informed choices when purchasing these essential power sources.

The Importance of Understanding Battery Pricing

With the rising importance of renewable energy sources and the increasing prevalence of electric vehicles, batteries have taken center stage. Knowing why batteries are priced the way they are is crucial, especially as they impact various aspects of modern life.

Mentioning the Availability of Affordable Accessories

Before we delve into the intricate details of battery pricing, it’s worth mentioning that obtaining affordable accessories for your devices can be just as important as understanding battery costs themselves. To make the most of your devices, finding reasonably priced accessories is a savvy move.

The Components That Matter

Cathode Materials

Role and Impact on Battery Performance

The cathode is a vital component, determining a battery’s capacity and voltage. Different cathode materials, such as lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4), can dramatically influence a battery’s overall performance.

Pricing Variations in Different Cathode Types

While lithium cobalt oxide offers high energy density, it comes at a higher cost due to the scarcity of cobalt. In contrast, lithium iron phosphate provides excellent stability but at a more affordable price point.

Cost Factors Associated with Anode Selection

Graphite is a commonly used anode material due to its cost-effectiveness and stable performance. However, newer technologies incorporating silicon anodes are more efficient but come at a higher price.

Electrolytes

The Crucial Role in Ion Movement

Electrolytes facilitate the movement of ions between the cathode and anode, a fundamental process in battery operation. The type of electrolyte used can impact a battery’s energy density and safety.

How Electrolyte Costs Affect Battery Prices

Liquid electrolytes are prevalent due to their low cost, but solid-state electrolytes are gaining attention for their improved safety. However, the production of solid-state electrolytes is currently more expensive, contributing to higher battery prices.

III. Manufacturing: From Raw Materials to Finished Product

Raw Material Extraction and Refining

Sourcing Critical Materials

The raw materials used in battery production, such as lithium, cobalt, and nickel, must be sourced globally. These materials’ availability and geopolitical factors can impact prices.

Environmental and Economic Implications

The extraction and refining processes of raw materials can have significant environmental and economic consequences, further influencing battery costs.

Cell Manufacturing Process

Assembly Line Techniques and Automation

Manufacturers employ various assembly line techniques and automation to streamline the production of battery cells, reducing labor costs.

Battery Pack Integration

Packaging, Safety Features, and Customization

Battery cells are integrated into packs with packaging, safety features, and customizations based on the application. These factors can impact the final price of batteries.

- The Mark-Up Mystery

Retail and Distribution Margins

The Journey from Manufacturer to Consumer

As batteries move from manufacturers to retailers and distributors, each entity adds a margin to cover their costs and generate profits, contributing to the final price.

Retail Markup Strategies

Retailers employ various pricing strategies, such as dynamic pricing and bundling, which can influence the perceived value and cost of batteries.

Brand Premiums and Market Positioning

Building a Reputation for Quality

Established brands often charge a premium for their batteries, leveraging their reputation for quality and reliability.

Pricing as a Competitive Advantage

Newer entrants may adopt lower pricing strategies to gain market share, influencing price dynamics.

Regional and Regulatory Influences

Tariffs, Taxes, and Import/Export Regulations

Government policies, tariffs, taxes, and trade regulations can vary by region and affect the import and export costs of batteries.

Regional Price Variations and Market Dynamics

Regional differences in demand, competition, and economic conditions can result in variations in battery prices.

Conclusion

Summarizing Key Insights

Understanding battery pricing involves dissecting the components, manufacturing processes, and markup mechanisms that contribute to the final cost. It’s a complex interplay of factors that directly impact our daily lives.

Emphasizing the Value of Informed Battery Purchases

Armed with knowledge about battery pricing, consumers can make more informed choices when selecting batteries for their devices, ultimately saving money and reducing environmental impacts.